How Santa Clarita Powder Coating can Save You Time, Stress, and Money.

Wiki Article

The Ultimate Guide To Santa Clarita Powder Coating Shop

Typically, thermoset powders are just applied via the ESD technique (santa clarita powder coating shop). This limitation exists since dipping preheated components into thermoset powder can cause any type of excess powder to cross-link due to built-up as well as recurring warmth within the fluid bed. As the cross-linking reaction triggers long-term adjustments to the powder material, such incidents would certainly result in excessive coating product waste.

Considering that metals can be electrically grounded, the finishing material is typically related to steel substratums by means of the electrostatic spray deposition method, however they can likewise be used through the fluidized bed approach. On the various other hand, considering that non-metals can not be sufficiently based, they call for that the powder coatings be used through the fluidized bed powder covering technique.

The Greatest Guide To Powder Coating In Santa Clarita

The process likewise enables for overspray product to be collected and also reused as opposed to thrown away, which decreases the quantity of waste product calling for disposal, increases the finishing product utilization price, and also decreases the expense of products gradually. Limitations of Powder Finish Although the powder covering procedure supplies a number of important advantages over liquid finishing, there are also restrictions to the process.As mentioned previously, substrate materials need to be able to hold up against the temperature level demands of the curing phase to be suitable for powder finishing applications. Even if a material can hold up against the heat, achieving an even coating can still confirm to be problematic, especially for thin or multi-color layers. Thin finishes are challenging to create as it is challenging to regulate the quantity of powder product that is applied to the substratum during the application stage while still ensuring an even layer.

While the powder finishing procedure can have lower costs with time, for details finishing applications, it might be more affordable to make use of fluid coatings. While powder covered parts commonly have quicker turn-around, big, thick, or heavy components tend to require higher temperature levels as well as even more extended treating as well as drying times; not only would these extended remedy timetables delay the production procedure, they would certainly also lead to higher energy expenses.

Little Known Questions About Santa Clarita Powder Coating.

These service providers can design and construct customized systems for finish particular components, which guarantees that the components are covered regularly and also to the required specs. Pricey as determined by the first financial investment, over the course of several years the last option can show much reduced cost-per-part. Some manufacturers might pick to finish finishing operations in-house, in which situation they would certainly require to invest in obtaining or buying powder finishing tools.

View Powder Coating Plus, Inc. Santa Clarita in a full screen map

Powder layer is a dry finishing procedure utilized to use a completely dry coating material. The covering material is comprised of finely ground particles of material as well as pigment for color, along with other additives for particular functions such as gloss or solidity. The dry powder finishing is provided to a spray gun idea that is fitted with an electrode to supply an electrostatic fee to the powder as it passes via a charged location at the gun suggestion.

Because its intro greater than 40 years earlier, powder layer has actually grown in popularity as well as is currently made use of by lots of makers of typical household and also industrial products. In The United States and Canada, it is estimated that even more than 5,000 finishers use powder to produce premium, durable surfaces on a wide selection of products.

Powder Coat Santa Clarita Can Be Fun For Everyone

In theory, 100 percent of the powder overspray can be recouped and also reused. santa clarita powder coating shop. Also with some loss in the collection filtering system systems and also on part hangers, powder utilization can be really high. Oversprayed powder can be redeemed by a recuperation system as well as returned to a feed hopper for recirculation through the system.The cured covering has a different chemical structure than the fundamental material. Thermosetting coverings are heat-stable and, unlike thermoplastic powders, will certainly not soften back to the liquid phase when reheated. Thermoset powders can additionally be used by spray application to develop thinner movies with better look than some thermoplastic powder finishings.

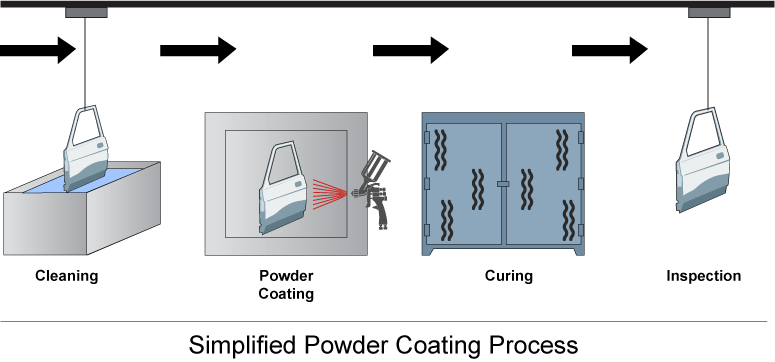

The process was introduced in the United click States in the 1960s, and quick development continued for the following 30 years. Pretreatment for Powder The initial step in the powder coating procedure is to prepare or pretreat the parts. The item to be coated is revealed to cleansing as well as pretreatment operations to ensure that surfaces to be covered are clean as well as totally free of oil, dust, oils, corrosion and other contaminants.

The Best Strategy To Use For Santa Clarita Powder Coating Shop

The specific pretreatment procedure chosen depends on the attributes of the coating and also substratum materials, and on completion usage of the product being coated. Pretreatments most typically utilized in powder finish are iron phosphate for steel, zinc phosphate for galvanized or steel substratums, and also chromium phosphates or non-chrome therapies for aluminum substrates.Dry-in-place pretreatment items, such as a seal rinse over an alkali steel phosphate, can decrease the variety of phases needed before powder finishing application. Chrome dried-in-place treatments work on multi-metal substratums and may be the single pretreatment required for some applications. Non-chrome modern technologies are commonly made use of too. Non-chrome aluminum therapies have come to be popular over time with outstanding efficiency their explanation residential or commercial properties.

They are after that ready to be coated. For many practical applications, a mechanical pretreatment such as sand or shot blasting can be utilized. With this technique, high-velocity air is utilized to drive sand, grit or steel shot towards the substratum, developing a support pattern on the component that enhances the attachment of the powder covering to the substrate.

3 Simple Techniques For Santa Clarita Powder Coating Shop

Learn More Mechanical blasting can be used alone or in addition to a chemical therapy. The blast operation creates an outstanding surface area for bond yet does not include any kind of additional corrosion security. santa clarita powder coating. In most cases, the blasted surface is initial covered with an ideal primer to add additional rust protection for blast-only surfaces.Report this wiki page